Titan Industrial Coating

TekShine’s toughest ceramic formula, built to protect equipment in the most demanding environments on earth. Whether you're dealing with corrosive chemicals, relentless abrasion, brutal UV exposure, or all of the above—Titan forms a long-lasting barrier that won’t back down.

From concrete batch plants and mining operations to agriculture, aviation, marine, powersports, gas & oil fields, and heavy-duty undercarriages, Titan locks in protection where it's needed most. It’s not just about making your gear look good—it’s about keeping it running longer, performing better, and standing strong in the face of abuse.

Multi-Surface Applications for Superior Anti-Corrosion

Color Toned Titan Industrial Coating

Titan Industrial Coating + Purge Concrete Cleaner

Built for Concrete Fleets. Engineered to Work Together.

In the concrete industry, equipment takes a daily beating from cement splatter, buildup, moisture, and harsh job site conditions. That’s why we developed a two-part system that works smarter—Titan Industrial Coating and Purge Concrete Cleaner—designed to protect your assets, cut maintenance time, and keep your fleet looking sharp.

Titan: The Long-Term Defense

Titan Industrial Coating is a high-build ceramic coating formulated to take on the harshest environments. Once applied, it creates a durable, hydrophobic barrier that repels concrete, slurry, moisture, and UV rays—preventing buildup and making rinse-downs effortless.

- Prevents concrete from bonding to the surface

- Resists abrasion, corrosion, and chemical damage

- Lasts up to 10 years with proper care

- Can be clear or tinted to match your fleet

Purge – The Smart Prep & Cleaner

Purge Concrete Cleaner is a non-toxic, pH-neutral solution that safely dissolves hardened concrete and grime without damaging finishes, metals, or sensitive components. Whether you’re prepping a surface for coating or maintaining a truck post-job, Purge lifts buildup fast—no acids, no corrosion, no harsh smells.

- Dissolves concrete without damage

- Long-lasting active formula (up to 72 hours)

- Safe for metal, rubber, and paint

- Leaves behind a surface ready for protection

The Power of the System

When Purge is used to clean and maintain Titan-coated surfaces, the results speak for themselves:

- Concrete doesn’t stick—it rinses off

- No more aggressive scrubbing or acid washes

- Fleet stays cleaner, longer

- Labor hours and maintenance costs drop

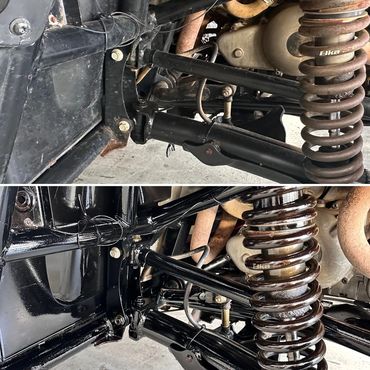

Protect Equipment & Undercarriages with Titan Industrial Coating

Product Functionality and Benefits

Our industrial coatings create a durable, non-porous barrier that prevents moisture, oxygen, and corrosive chemicals from reaching the surface. This barrier significantly reduces the risk of rust, oxidation, and surface degradation, even in highly aggressive environments like those exposed to salt, chemicals, or industrial pollutants.

Titan can be applied to metal, painted surfaces, plastics, and even some composites. It also works on rubber components.

Yes, our industrial coatings are engineered to perform exceptionally well in chemically aggressive, marine, and high-humidity environments, providing long-lasting protection even under continuous exposure.

Application Process

Our coating is designed for spray application only, ensuring even coverage and maximum adhesion. This method is ideal for both large and intricate surfaces, providing a seamless protective layer.

Yes, surface preparation is critical. Surfaces need to be thoroughly cleaned, degreased, and, in some cases, sandblasted to ensure optimal adhesion for the spray application. Detailed preparation guidelines are available upon certified training.

Drying times depend on environmental factors and the coating thickness, but most applications dry to the touch within 2-4 hours and fully cure within 24-72 hours.

Yes, our sprayable coating is designed for on-site application, allowing for flexibility in construction and masonry projects. This makes it ideal for protecting large structures, equipment, and materials in their actual working environments.

Durability and Maintenance

Depending on the environment, our coatings can last 10-15 years or longer without significant degradation, providing outstanding long-term value.

Maintenance is minimal. Routine inspections are recommended, but reapplication is rarely needed unless the coating has been physically damaged.

Yes, our coatings are UV-stable, temperature-resistant, and designed to withstand mechanical wear, making them ideal for demanding construction environments.

In the rare event of damage, the affected area can be spot-repaired with our repair kits, ensuring seamless restoration without the need for full reapplication.

Cost and ROI

By preventing corrosion and extending the lifespan of materials, our industrial coatings can reduce maintenance and replacement costs by up to 50-70%, delivering significant long-term savings.

Yes, we offer discounted rates for bulk orders and long-term contracts to support large-scale construction projects.

Compatibility and Safety

Our coatings are formulated to be environmentally conscious, featuring low VOC’s to meet green building standards.

The application process is straightforward and safe when the correct PPE and ventilation are used. We provide detailed safety data sheets for all our products.

Performance in Construction-Specific Scenarios

Absolutely. Our coatings provide superior protection against de-icing salts, acid rain, and other pollutants, making them ideal for outdoor applications.

Our coatings are highly durable and resistant to abrasion, oil, and grease, making them perfect for protecting machinery and equipment from wear and corrosion.

Customization and Support

Yes, industrial coatings like Titan Coating can absolutely be tailored to specific project requirements, including color customization.

Yes, we provide comprehensive technical support, including application training for your team or third-party applicators.

We offer an amazing guarantee that the product will last 10+ years when proper maintenance is performed. We also back it with unlimited training and product support to ensure you get the absolute most out of our industrial coatings

Have Questions?

Copyright © 2025 TekShine Industrial - All Rights Reserved.

Protect. Preserve. Perform.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.